The new diamond range

Problem solving

Diamond cutting

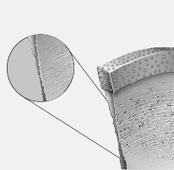

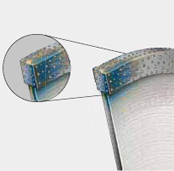

Undercutting

The base blade underneath the segment wears down too quickly. This can lead to segment loss.

First possible cause:

The layer under the material you are working on is too abrasive.

Preventive measures:

Consider using the step cutting method. Cut the top layer first with a concrete disc and change to an abrasive diamond cutting disc to cut the subsurface material.

Second possible cause:

The cutting disc has been used to cut a material that is too abrasive.

Preventive measures:

Use a disc that is suitable for the material. For help with this, observe the application recommendations on the packaging or consult the product recommendations. Bosch diamond cutting discs for asphalt, for example, have special protective segments to prevent undercutting.

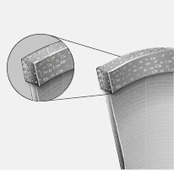

Glazed diamond segments

The diamond bond is too hard and does not wear down quickly enough to release new, sharp diamonds. The diamond cutting disc becomes blunt.

Possible cause:

The selected diamond cutting disc may not be suitable for the material you are working on, i.e. the material is too hard.

Preventive measures:

Select a cutting disc that is suitable for the material. Diamond cutting discs with a soft bond, e.g. Bosch Stone, are recommended for hard or very hard materials. Resharpening (brief cutting in very abrasive material) can help in the short term.

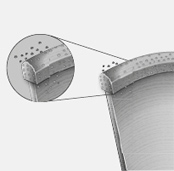

Excessive segment wear in general

The diamond bond is too soft and wears down too quickly. This causes premature release of diamonds that would actually still be able to cut.

Possible cause:

The selected diamond cutting disc may not be suitable for the material you are working on, i.e. the material is too abrasive.

Preventive measures:

Select a cutting disc that is suitable for the material. Cutting discs with a hard bond, e.g. Bosch Abrasive, are recommended for abrasive materials.

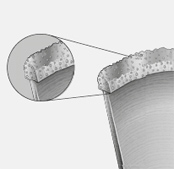

Excessive segment wear on the sides

The diamond cutting disc has been severely tilted in the kerf.

Possible cause:

You tried to cut curves or use the disc for grinding although it can only be used for cutting. If the disc has not been misused, check the toolholder or the diamond cutting disc.

Discolouration on segment and base blade

The diamond cutting disc has overheated, which reduces the lifetime.

First possible cause:

The necessary cooling interval was not applied or the load on the diamond cutting disc is too great.

Preventive measures:

Do not press too hard. Instead try to feel the optimum feed rate. The weight of the machine will provide enough feed pressure.

Second possible cause:You were performing work for which wet cutting is recommended, but not enough cooling water or no cooling water at all was used.

The right accessories for your job

The new diamond range

Here you will find more information about our complete range with more than 200 products